This piece first appeared in the Modern Producer Magazine - Special Thanks to Britt Roman and Munters!

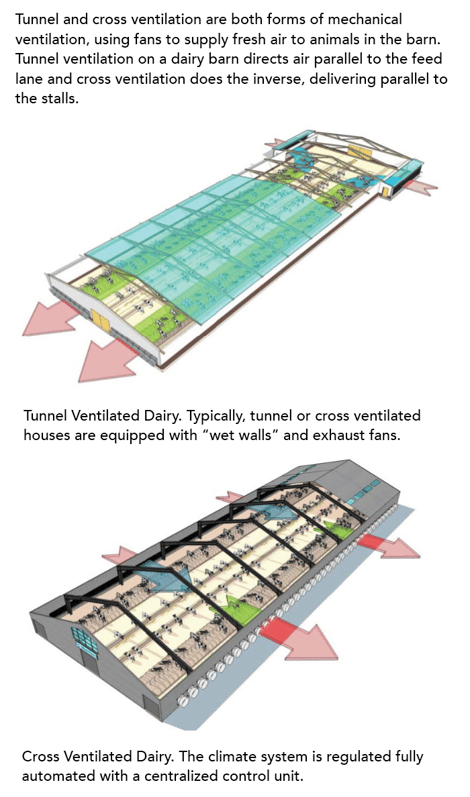

The dairy operation at Vir-Clar Dairy in Fond du Lac Wisconsin is like many other dairy operations in the Midwest, a family-owned farm in its fourth generation. As a growing operation, Vir-Clar has evolved over time and they’ve added new barns, their most recent addition was a cross ventilation barn which now stands next to a naturally ventilated and a tunnel ventilated barn. Today they milk more than 2,000 cows.

The latest barn was built with cow comfort at the forefront. “Living in the Upper Midwest, ventilation not only has to perform during those couple of weeks when we get hot weather, but also it has to perform in the winter when temperatures can become pretty extreme,” said Grant Grinstead of Vir-Clar farms.

The latest barn was built with cow comfort at the forefront. “Living in the Upper Midwest, ventilation not only has to perform during those couple of weeks when we get hot weather, but also it has to perform in the winter when temperatures can become pretty extreme,” said Grant Grinstead of Vir-Clar farms.

Ventilation systems are engineered to provide precise control of the climate inside the facility, even when the climate outside of the building is extreme or changing. Heat stress can be a problem all year, or just for a part of the year. Providing proper ventilation has a dramatic effect on overall productivity and comfort. Dairy cows not affected by heat stress produce more milk; have lower respiration rates, higher conception rates (resulting in more cow pregnancies) and overall better health.

As they began their search for what to build next, they toured many other barns evaluating ventilation systems and “Saw a number of barns that had clusters of fans running at full-speed, so you would find zones within the barn that had maybe too much ventilation,” said Grinstead. He continued, “Cows will congregate where the air is better.”

The Design

Vir-Clar ultimately chose Munters for ventilation. They installed 66 Vortex 55” fans equipped with Munters Drive, which can be set to pre-programmed efficiency options or be customized to optimize airflow and ventilation depending on the season, size of the building, animal age, and other factors that affect production. Uniform climate inside the building means the cows can spread out among the available space, instead of clustering together inside the building. Vir-Clar installed ten AT24 Ridge top fans which exhaust air out of the building as well.

Vir-Clar also installed sensors spread throughout the barn to get an average temperature reading so they know when to turn the fans on. The communication goes through a single line to their Farm Guard controller. “The internet-enabled controller is accessed with Farm Net software so Grant can log in remotely anywhere he has internet access and view any of the systems in the barn. He can view the temperatures, make adjustments as needed throughout the barn – he can do anything remotely that he can do standing in front of the controller,” said Jonathan Chalupa, sales representative for Munters Corporation.

Pay Back

Vir-Clar evaluated the initial cost, but also the overall lifecycle cost of the design. “Munters is a premium product, but when we look at the lifecycle, and base it on historical temperatures in Wisconsin, we are saving energy in the long run with many variable speed fans,” said Grinstead.

Grinstead noted, “Munters provided wiring diagrams that the electricians could easily follow. The Munters Drive allows flexibility and, allows us to capture energy savings which is at the forefront of our business. Instead of just shutting fans off to capture savings, the system ventilates the barn as designed and does the work for us.”

Munters Drive also reduces noise levels and maintenance requirements.

“Munters is a premier product. The upfront costs were high, but you have to look at the lifecycle costs. After 25 months, we’re ahead of the game on energy usage. And that’s assuming rates stay the same. If rates go up, it’ll be an even bigger cost savings,” said Grinstead.

The Munters Drive works with new installations or can be retrofitted to existing fans and control systems—even those of other manufacturers. With its straightforward design, there is no need for expensive, complex wiring.