Including tunnel ventilation in turkey finisher barn designs has become popular among poultry producers, but does it regulate temperature any better than natural or other mechanical poultry barn ventilation systems? We believe tunnel ventilation systems are more efficient and less costly, and our team has a wealth of experience designing and installing tunnel ventilation into turkey finishing houses. Read more on why you must include tunnel ventilation into your next turkey barn design.

Mortality Rates Decrease with Tunnel Ventilation

By drawing in air through large openings with evaporative cooling pads or misting nozzles on one end of the building and pulling it to the other end of the building, the high velocity air movement created by these systems cool the birds more efficiently than conventional systems. Systems can also be designed with high or low pressure misting systems staged down the length of a tunnel ventilated barn to increase evaporation rates in higher humidity areas. Rather than cooling pockets of the barn, the air that is drawn in is pushed through the whole building creating a cooling wall that reaches all areas of the barn. Because the air is moved in a uniform and constant way, tunnel ventilation allows you to control the building temperature more effectively without causing large spikes and drops. This allows you to reduce the amount of heat stress you put on the birds, which in turn lowers the chances of mortality. Not only will your mortality rate decrease, your bird performance will increase.

The greatest benefit for turkeys in a tunnel ventilated barn is the cooling that is achieved through a “wind chill” effect. The air flowing over the heads and upper bodies of turkeys can significantly help remove excess heat and provide and sense of cooling for the birds.

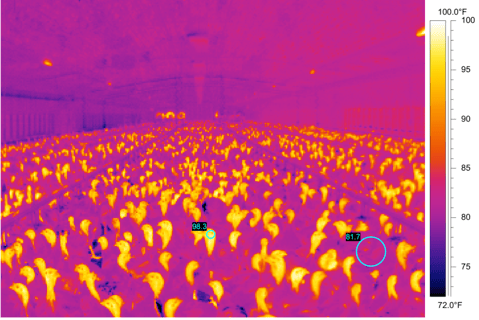

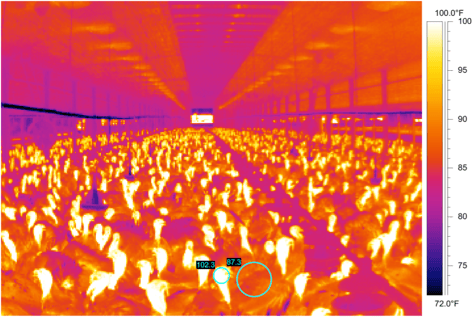

In the thermal images below, you can see the effects of tunnel ventilation. Image 1 shows a barn that is ventilated using tunnel ventilation and some low-level mist cooling. Image 2 is from the same date and time in a barn that is 300’ west of the tunnel ventilated barn. The second barn is naturally ventilated with curtain side walls, sprinklers over the birds and circulation fans. As you can see, with an increase of air flow and minimal evaporative cooling, we’ve been able to significantly reduce the temperature on the heads of the turkeys.

Image 1. Tunnel ventilation with evaporative mist cooling.

Image 2. Natural ventilation with sprinklers and circulation fans.

What About the Investment and Operating Costs?

It will obviously cost you if you need to transition your poultry house to tunnel ventilation. It is also true that it typically uses more electricity to operate tunnel than natural ventilation. While it seems like it is not worth incurring the extra costs, operating with tunnel ventilation will save you money in the end. It is worth noting that tunnel ventilated barns typically have much higher insulation levels which will lower heating costs in winter. An average insulated curtain may have an R-value of 4-6 while a properly insulated 6” wall should have at least an R-value of 19. Depending on your location and meteorological circumstances, heat savings may very well offset a majority of additional electricity that is used to tunnel ventilate in summer.

By regulating temperature more consistently in summer, causing less heat stress and having greater control of your poultry barn ventilation in winter, your mortality rate decrease and your bird production increase will outweigh the costs of operating the system. Like we have mentioned before, New Standard does not believe in designing inefficient and poorly planned buildings; saving money on capital investment can cost more in the long run. We want you to have a building that is going to increase your production, be easier to work in and manage, and decrease the amount of stress on your animals. In the end, your profits will go up, outweighing the extra costs, if you design and build an efficient barn.

The New Standard Group team is always willing to have a conversation with you about your barn, even if you are not looking to remodel or build new soon. The swine and poultry industries are changing for the better, and we want to help you understand how you can keep up while also increasing your production. If you are interested in speaking with one of us today, click the button below.