The New Standard team is all about the advancement of taking care of our animals in this industry. So are quite a few of our producers we come across in this field. Over the course of our time as a company, we were always curious what the future of farming could be. We sat down with a handful of producers to ask just that. What they enjoy currently, and what, realistically or not, would they like to see in the next 10 years for the advancement of farming.

So What's Next: Tim Friedel

07.26.2021

So What's Next: Chet Mogler

07.23.2021

The New Standard team is all about the advancement of taking care of our animals in this industry. So are quite a few of our producers we come across in this field. Over the course of our time as a company, we were always curious about what the future of farming could be. We sat down with a handful of producers to ask just that. What they enjoy currently, and what, realistically or not, would they like to see in the next 10 years for the advancement of farming.

1910 Elementary Agriculture

07.21.2021

The Case of the Meishan Boars

07.16.2021

So What's Next: Hunter Thomas

07.12.2021

The New Standard team is all about the advancement of taking care of our animals in this industry. So are quite a few of our producers we come across in this field. Over the course of our time as a company, we were always curious about what the future of farming could be. We sat down with a handful of producers to ask just that. What they enjoy currently, and what, realistically or not, would they like to see in the next 10 years for the advancement of farming. Below are their answers.

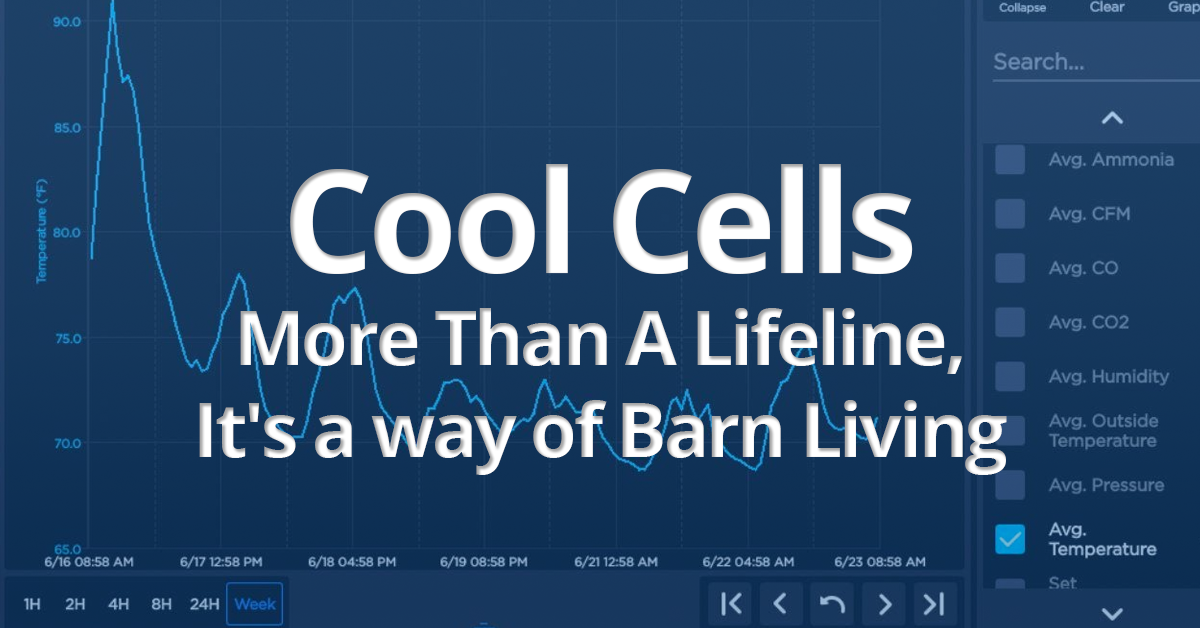

A week ago, I put up a screenshot of what happens when you turn on cool cells for the first time. We saw a temperature drop of more than 7° F in a 15-minute window, which was excellent and certainly made Michael at Goldenview Colony happy. There is, however, so much more to cool cells, and understanding how to maximize their effectiveness can allow even more impressive results.

The University of Alberta, a top 5 Canadian University, was ready to update their sow stall barn into an ESF. They contacted the team at New Standard to begin the design process. By the Spring of 2018, they had finalized the plans. They needed a design for 120 head of sow. The team was in contact with Jay Willis, the Research Stations Manager, Faculty of Agricultural, Life and Environmental Sciences.

So why do you need to be thinking about cooling those birds this spring? Because when June arrives, those full-grown turkeys will really need a cool breeze to stay in top condition.

February and March are the best time to start thinking about Tunnel Ventilation.

The Breakdown

Poults placed now are the first heavy toms to see heat for the year. Around 18 -22 weeks, these birds are fully developed and have not seen real hot weather, let alone been acclimated.

Grown toms have a relatively low thermal neutral zone, ideally, around 55 degrees F. As we all know, June temperatures can spike to 90°F (or higher). Additionally, humidity can also spike in June which makes matters even worse. With poor ventilation and sub-par cooling, June can be the hardest month to keep heavy toms alive and growing.

Here's the Facts

Older turkeys at this time of year have not acclimated to brutal summer conditions. Heat and the combination of humidity will cause birds to perspire. If birds cannot cool down, their respiratory system becomes affected by the humidity and sweat. The result is birds' lungs filling with fluid, causing reduced oxygen intake, leading to heat related heart attacks and many other issues.

Without the desired temperatures or a properly engineered wind chill effect to keep these birds cool, several issues will arise, including:

- Rise in mortality

- Off feed events, because birds are not eating

- Feed conversion going bad

- Your bottom line is affected

Benefits of Tunnel Ventilation

How are your birds going to handle this heat? Now is the time to make sure you are planning for renovation and upgrades because June is the time you need your systems working.

Here at New Standard, we stand behind Tunnel Ventilation technology because we've seen the results. Here's why:

Cools the birds naturally through ruffling feathers/wind chill effect

The most significant benefit for turkeys in a tunnel ventilated barn is the cooling achieved through a "wind chill" effect. The air flowing over the heads and upper bodies of turkeys can significantly help remove excess heat and provide a sense of cooling for the birds.

Allows you to cool the barn more efficiently with evaporative cooling

By drawing in air through large openings with evaporative cooling pads on one end of the building or placing mister or fogger nozzles down the length of the barn, you can use evaporation of water to remove heat energy from the air flow. With optimal conditions, a drop in temperature within the barn of 10-15°F (5-8°C) is certainly achievable.

Evaporative cooling is only a good option sometimes.

Evaporative cooling is a great tool to incorporate but if the humidity is above 80%, the cooling effect is minimal and may harm your birds as their respiratory system may not be able to exhaust moisture well enough if it is too humid. That means it is necessary to have your tunnel ventilation engineered to maximize wind chill even when you cannot use cool cells or foggers.

Measure CO2 to ensure there is a high quantity of oxygen

Just like humans, turkeys breathe in oxygen and exhale carbon dioxide. When the heat levels and possibly humidity levels are high, it is paramount that oxygen levels within a barn are as high as possible. This is especially true for poultry as they perspire in their respiratory system and can experience reduced lung capacity if the humidity is too high to dry out their lungs while panting.

Tunnel ventilation allows for increased air exchange as well as the wind chill effect, thus allowing maximum oxygen saturation within the barn.

Next Steps

If you are unsure about the quality of your barn ventilation, contact New Standard. We are here to help you assess your needs and, when needed, deliver the quality solutions, and work you need to keep your turkeys happy. We have a proven track record that cannot be matched when it comes to design and engineering for tunnel ventilated turkey barns.

The retrofit project at Greenwald Colony is well underway. The Greenwald Colony is converting their traditional gestation stall barn into a loose sow housing set up with an electronic sow feeding systems (ESF). Kevin Kurbis (New Standard Ag) had designed the project and is facilitating the entire remodel. This video shows the barn (still mostly stalls) at the beginning of the transformation. Kevin explains the process and many of the steps we are going to see along the way. So without further delay - here's Kevin!

A completely new hog production facility upgrade has spanned the last four years on the Neudorf Colony in Crossfield, Alberta, Canada. "Kase from New Standard West has been great. From the first meeting, he heard what we were looking for and created a drawing that would meet our needs as well as creating a system that would help in achieving results," says Jerry, second hog manager at Neudorf Colony. The following case study outlines the project and what services and equipment New Standard Group provided in the barn build and construction and support and system implementation after the build.